Cutting Processes

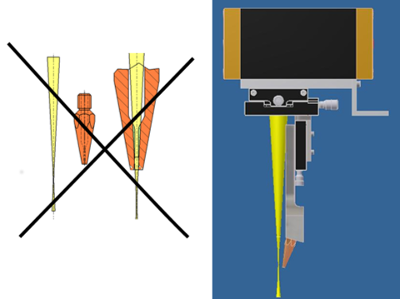

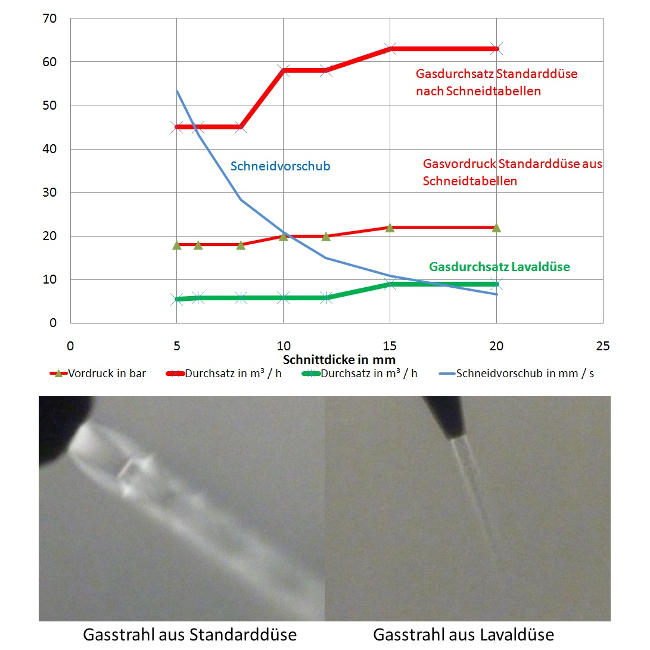

The process "Laser Beam Cutting" needs two kinds of tools: one laser beam and one cutting jet. Today the cutting jet is formed as jet from high pressurised gas with larger diameter. The reason for the large diameter is that the focussed laser beam has to passe through a coaxial cutting nozzle. Because of its hyperbolic caustic the part of the laser beam passing the nozzle has a diameter larger than the focus. So the diameter of the nozzle bore has to be larger than necessary, figure 1. The conventional used bore diameters are between 1.5 mm to 3 mm - depending on work piece thickness. The consumption of cutting gas is respectively high and lasts up to more than 60 m³ per hour, figure 2. That should not be!